Background

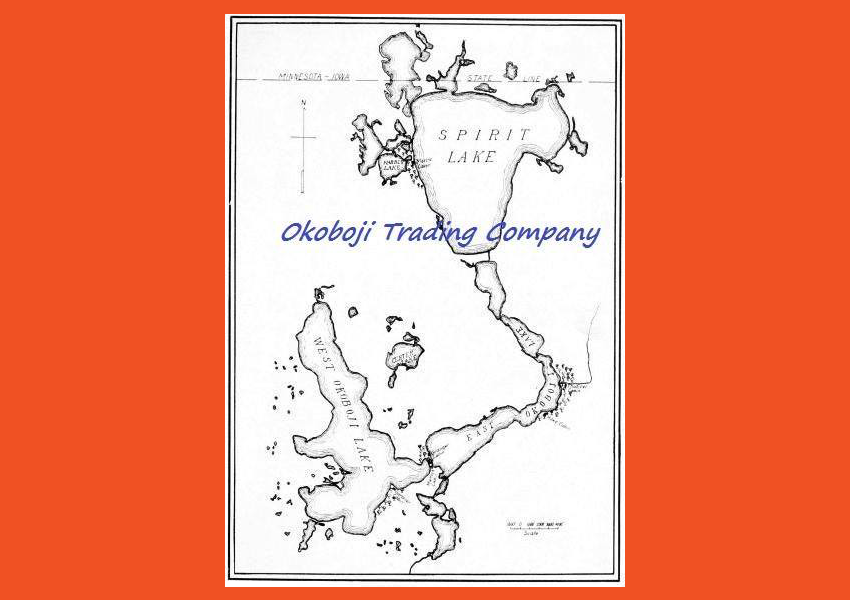

Okoboji Trading is a full-service woodworking shop offering Americana, wall art, tables, whiskey boxes, bathymetric lake maps, CNC, Laser, and epoxy work. They combine traditional woodworking techniques with modern technology, including CNC and laser machines, to create intricate, high-quality products.

The Challenge

Okoboji Trading faced significant challenges with outdated and inefficient laser machinery. Using Orion and Glowforge lasers severely limited their production capacity and ability to enter new market niches. The Orion laser was unreliable and difficult to service, while the Glowforge was too slow for intricate pieces and could not handle certain materials like tumblers and metal.

The Solution

The shop invested in AP Lazer, which offered open architecture, robust support, and significantly greater capacity. Despite initial hesitation and a delayed setup, the new laser machine was put in place, allowing the immediate production of more complex items such as lake maps and drinkware.

The Results

- Operational Efficiency: Immediate improvement in production capacity and the ability to handle new product types.

- Sales Growth: Sales doubled in the first year and increased 2.5X in the second year.

- Productivity Boost: The new laser machine allowed the shop to complete tasks faster and more precisely.

Conclusion

Integrating the AP Lazer machine revolutionized the shop’s operations, enabling it to produce more intricate and higher-quality products efficiently. This strategic upgrade was crucial for their business growth and market competitiveness.

Contact us today to learn how our open architecture laser machines can transform your woodworking business and boost your production efficiency