What does it mean to be a part of the AP Lazer Family and why is it so beneficial to your business? We checked in with Kevin Smith of Kevin’s Custom Woodwork & Lasering to find out about his experience since purchased an AP Lazer!

Where did you find out about AP Lazer?

While researching laser engraving machines for my woodworking business(a $69 billion market) I did a Google search and AP Lazer was one of the companies that came up in the search engine.

How did you fund your laser and when do you expect to have it paid off?

I looked into the financing the laser thru AP Lazer and after comparing interest rates through the financing company, my bank, and a credit union that I am a member of, I decided to go thru the credit union and refinanced my personal vehicle. The original finance term for my loan is 48 months. I am currently looking at having the loan paid off in less than 24 months. I set a goal of 18 months and am very optimistic that I will meet that goal.

What was the biggest selling point of our laser?

When looking at making any major equipment purchase, I take my time and do a lot of research. After reading many reviews, looking at specs, and getting on the AP Lazer Before You Buy Facebook page, I made my decision to buy my AP Lazer. Although the open-architecture of the AP Lazer interested me, the information that I found during my research on ease of use, customer support, and 24/7 Lifetime Technical Support weighed the most on my decision. Then after spending several hours with Larry and Janet Neukirch as they demoed their laser and answered tons of questions, I made my decision.

How difficult is it to run an AP Lazer?

Because I already had a CNC Router and was familiar with g-code and design it wasn’t that bad at all. After ordering my laser, I downloaded a trial version of CorelDraw and started getting familiar with it. I had a couple of designs programmed and had my first piece lasered within ten minutes of getting my laser set up.

What have you used AP Lazer tech support for and how was your experience?

The first time for calling tech support was during the initial set up. The instructions were for the old-style frame (this has since been updated) and I was having trouble setting the focus. After ending the call, I studied the laser and figured out that the cross supports that the laser sits on were put on backward. Then while adjusting my mirrors, my laser stopped working and another call was placed. A new part was sent out and installed however it did not fix the problem. A third call was made and the problem was narrowed down to two possible faulty parts. Both parts were sent overnight and after changing the first, my laser was up and running again. The only other issues I’ve had to call tech support for were software issues and were resolved within a matter of minutes. Overall, I would rate my experiences with tech support as very good.

What do you like about the AP Lazer family?

Their willingness to help with programming issues and share ideas. When someone joins the AP Family they are welcomed and made to feel like they belong. There are several really talented people in the AP Lazer family of users and within a matter of minutes, any questions I’ve had were answered by several of the members. I have even heard of members offering up their own lasers to help other members when their lasers were down waiting on parts. That to me is what truly makes this group a family.

Another thing that really stood out and meant a lot to me was the extra effort put in by the guys at AP. After I placed the order for my laser, I mentioned in a post that I was going to be like a kid on waiting on Christmas morning. One of the family members saw the post and made a call to AP with a special request. When the delivery truck pulled up in front of my house there was a huge Christmas present with a special laser-engraved tag inside. The guys at AP spent several hours and fourteen rolls of wrapping paper to make my delivery special. I have that tag hanging over my laser.

Did you start your business when you purchased the AP Lazer or did you purchase it to diversify an existing business?

I already had been doing custom woodwork before buying my laser. I did buy it to enhance what I was already doing. The laser has opened new doors as far as the products I’m now able to offer and has also reduced the production times on some of the items that I was producing before.

What is your business and how would you describe it?

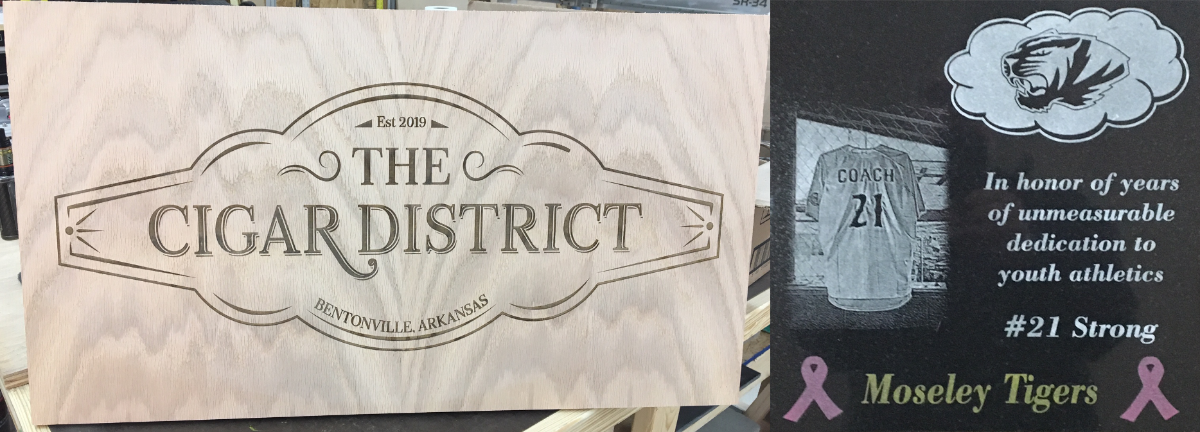

The best way to describe my business would be “a full-service custom woodworking shop” I produce a large variety of items including but not limited to custom furniture, cabinets, award plaques, signs, and wall art. Basically, if someone has the vision, I’ll try to make it a reality.

How would you describe the impact owning a laser has had on your business?

Like I said before, the laser has allowed me to take on orders that I had previously turned away. And it has also greatly reduced the amount of time it took to produce some of the items that I had been making. The plaques I was making before used to take me around 1 hour to produce and now I can do one in around 15 minutes. This reduction in time has allowed me to take on more customers.

How have you marketed your laser business and products?

Currently, the only marketing I do is my Kevin’s Custom Woodwork and Lasering Facebook page. The majority of my business has come from word of mouth and repeat customers.

Do you have a website, and do you think it is necessary?

Currently, I do not. I have thought about building one but have been keeping a backlog of orders without it.

Where do you source your blanks from?

For the plaques and signs, I make all of my own blanks from hardwoods that I buy from a local sawmill. I also get material from Johnson Plastics and BF Plastics. A lot of the other stuff, I try to buy local.

How do you determine pricing for your products?

I take the total cost of materials and add what I feel is a fair charge for labor. I also check the market in my area to see what people are willing to pay for certain products.

When you first started out with a laser what products did you start with?

Having bought my laser and taking delivery in late November, the first items were small Christmas gifts. Tumblers, cutting boards, coasters, and glass baking dishes were among the first item I produced with it.

What is your favorite part about using the laser?

The wide range of materials you can work with and the speed at which you can do it.

What ways do you see yourself using the laser in the future that you haven’t tried yet?

I would like to learn how to produce 3D engravings.

What is the most creative/unusual object you’ve engraved?

I would have to say a shell casing. One of the guys at the Fire Department I retired from asked me if I could engrave it for his 12-year-old daughter. It was the shell from her first whitetail deer harvest.