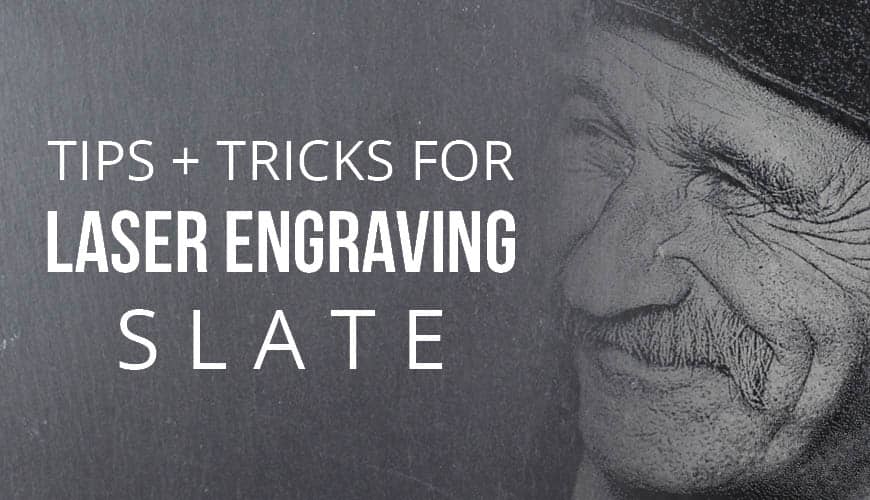

— How To Laser Engrave Slate: 4 Great Tips For Epic Results

With most laser machines being utilized for common materials like wood, granite, or leather, saturating the laser-engraved market, you need to stand out in the crowd with unique materials that offer beautiful results. Laser engraving on acrylic, for instance, is highly suitable for vector engraving at high speeds, and practical testing on small acrylic samples ensures consistent results and settings. That is when a laser etching machine for slate comes into the picture. Slate can exhibit a range of colors, including green, due to chlorite, a green micaceous clay mineral, which plays a role in its aesthetic appeal and various applications. So, what is the best laser engraving machine for slate? Well, AP Lazer has you covered!

Best Laser Engraving Machine for Slate: Slate as a Niche

Slate is one of the few options that fit that niche. A softer, fine-grained, deep gray stone slate has the potential for various projects. By nature, the stone has a property called fissility that displays many thin, flat layers. This is what gives slate its rustic, beveled edge. However, it also has a clean-cut, smooth edge to fit any application.

With some testing, research, and a little trial-and-error, our technicians have found some tricks for the best results when using a laser etching machine for slate. The laser’s light interacts with the slate’s dark surface, making settings and preparation crucial to achieve the desired contrast and detail. Using multiple passes can be essential for achieving quality results when laser engraving on slate. If you’re skeptical or curious, feel free to check out some of the fantastic work already produced on our Facebook- Before You Buy group

Prepare the Artwork

Download and edit engraving files to your liking. Once a design has been modified, the next step should be engraving. Place the paper onto the laser. If you want to be sure about the placement of your design, create vector boxes and place them on the machine with the red dots pointing in.

Engrave Slate coasters

Clean the stone of any natural dust or particles with a damp cloth and allow it to dry.

Spray the stone with a thin but even layer of clear coat finish. Allow at least an hour to dry (refer to your can of clearcoat for more specific drying times)

Align and engrave with your AP Lazer machine

Wipe off with a cloth to remove any residue from the laser process

Enjoy the fantastic results the slate has to offer!

With our 100W laser, we’ve found the following settings to produce some excellent results: a speed of 20 and a power of around 22. Please do a little testing to find a combination you prefer!

Slate Applications

Slate is incredible for line drawings and portraits; it has shown excellent precision with high contrast and detail. Using our laser engraver for slate, we’ve produced a few different projects on slate, check out the results below:

When engraving, it is crucial to correctly position and focus on the image to achieve explicit representations, whether working with raster or vector techniques.

There are dozens of slate applications, and a laser will only enhance the slate’s appearance. Small items such as cheese boards, coasters, and photo tiles can be mass-produced to make a profit. Larger laser-engraved slate applications are ideal for indoor and outdoor areas, including pool areas, patios, fireplaces, verandas, and flooring. It’s essential to have a big machine to accommodate larger jobs; the more significant the project, the more profit you will make!

Why AP Lazer for Slate Engraving?

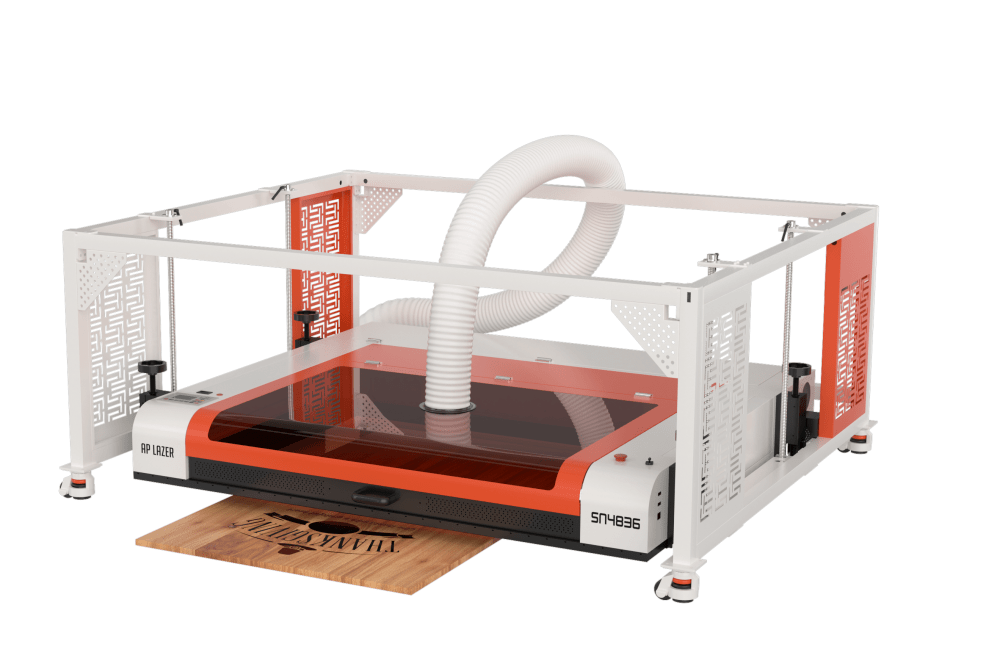

You probably know that dozens of laser etching machines can engrave slate. But you may not know that AP Lazer is unlike all of them. AP Lazer’s two-part, open architecture design allows users to engrave virtually any material of any size. This patented, revolutionary design eliminates the physical size limitations that hold back so many others on the market.

AP Lazer’s features will allow you to blast out the competition by offering services they can not, as your production is now limited only by customer requests. A removable top makes it possible to laser engrave directly onto flooring of all types. See the AP Lazer difference here.

Adjusting the power, speed, and dot size settings is crucial to achieving precise and accurate engravings on slate. Testing different configurations will help you find the optimum settings for the best engraving quality and detail.

Lastly, compared to some other stones, slate is competitively priced. As a unique stone that offers outstanding potential, the profit margins for your business are huge!

Download our FREE Business Growth Guide

If you’re interested in slate blanks in many different shapes and sizes to capitalize on owning your laser etching machine, we now feature them in the AP Lazer Webstore. Click here to see what we offer.

Want to learn more about this exciting opportunity? Call us at (800) 585-8617, email us, or fill out our contact form.