If you need a permanent and long-lasting solution that provides more customization and personalization options than traditional brick marking methods, a brick engraving machine is your answer.

Bricks have been around for hundreds of years; they are one of the earliest man-made building blocks. Their durability and the fact they withstand the test of time makes them an ideal choice for fundraising and donor campaigns.

A Hassle-Free Brick Engraving Machine for the Job

If you’re looking to provide laser engraved bricks for fundraising or donor campaigns, the essential tool you will need is a reliable brick engraving machine that can tackle the job. Your brick engraving machine will save you time, eliminate extra costs and produce fundraising bricks that will last a lifetime. This is just the tip of the iceberg when it comes to the advantages of engraving bricks.

When Choosing a Brick Engraving Machine Consider the Following:

If you’re looking to provide laser engraved bricks for fundraising or donor campaigns, the essential tool you will need is a reliable brick engraving machine that can tackle the job.

Your brick engraving machine will save you time, eliminate extra costs and produce fundraising bricks that will last a lifetime. This is just the tip of the iceberg when it comes to the advantages of engraving bricks.

- Power – to engrave brick, you will need a C02 laser with at least 60 watts of power. Brick engraving can be achieved with a lower power laser machine; however, you will more than likely need to do a few passes to create a desirable look.

- Size – You never want to be limited by the size of your brick engraving machine. Look for a machine with a large bed so you can engrave multiple bricks at once to streamline your productivity and efficiency.

- Versatility – You never want to be limited to the types of engravings you can offer so make sure to research what makes each laser machine different. Our brick engraving machines feature a patented open architecture design that makes it possible to engrave large and bulky objects. See it in action here.

- What’s IncludedWith your Laser? Will there be additional accessories, software, or that will come as extra costs? All of our lasers are sold as turn-key packages, meaning everything you need to get started is included, and you won’t run into any extra costs.

- Experience – Make sure the company you are buying the laser form has experience with brick engraving.

- Warranty and Support – Purchasing a laser machine is just the beginning of your journey. Consider what the support post-purchase is like. Is there a warranty? What does it cover? How long does it last?

A Five Figure Income in as Little as 60 Days

With the right brick engraving machine, you can make a substantial amount for your business in a short amount of time.

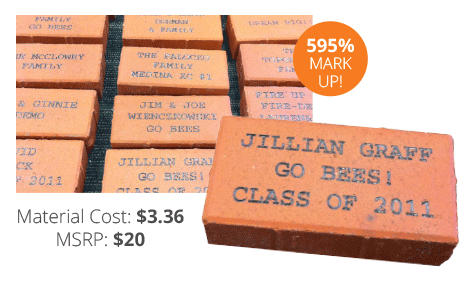

A quick online search shows companies charging anywhere from $13 – $50 per brick engraving, depending on the size of the brick and the complexity of the design.

Because it takes hundreds of bricks to create a sidewalk or walkway, a single brick engraving job has the potential to pay for your entire brick engraving machine! We have a few customers who have entirely paid for their laser machine with just one or two brick orders.

Fundraising and donor projects often carry on for years to come, resulting in a long-term revenue stream for your business.

With your own brick engraving machine, or you will be in complete control of your own projects.

Provide high-quality laser engraved bricks, and everyone involved will be happy. Your customer will be thrilled with the quality of the laser engraved brick you produce, donors will be honored to have their legacy in a permanent setting, and you will have a nice profit in your pocket.

Who Needs Fundraising/Donor Bricks?

We’ve done the hard part for you and compiled a list of 13 organizations that are interested in laser engraved bricks. If you are looking to contract with an organization to provide laser engraved bricks, there are many opportunities available as these types of organizations are always trying to raise funds.

Try reaching out to the following types of organizations to lock in high-profit brick engraving jobs:

- Donor Recognition

- Hospitals

- Memorials

- Clubs

- Fraternities/Sororities

- Charitable Organizations

- Parks and Recreation

- Zoos

- Sports Teams

- School Fundraising

- Universities

- Religious Organizations

- Museums

5 Advantages of Laser Engraved Bricks

With today’s brick engraving technology, there is no reason to use these outdated methods such as sandblasting or pantographing when you have a high-tech tool that can produce perfect brick on mass, every time.

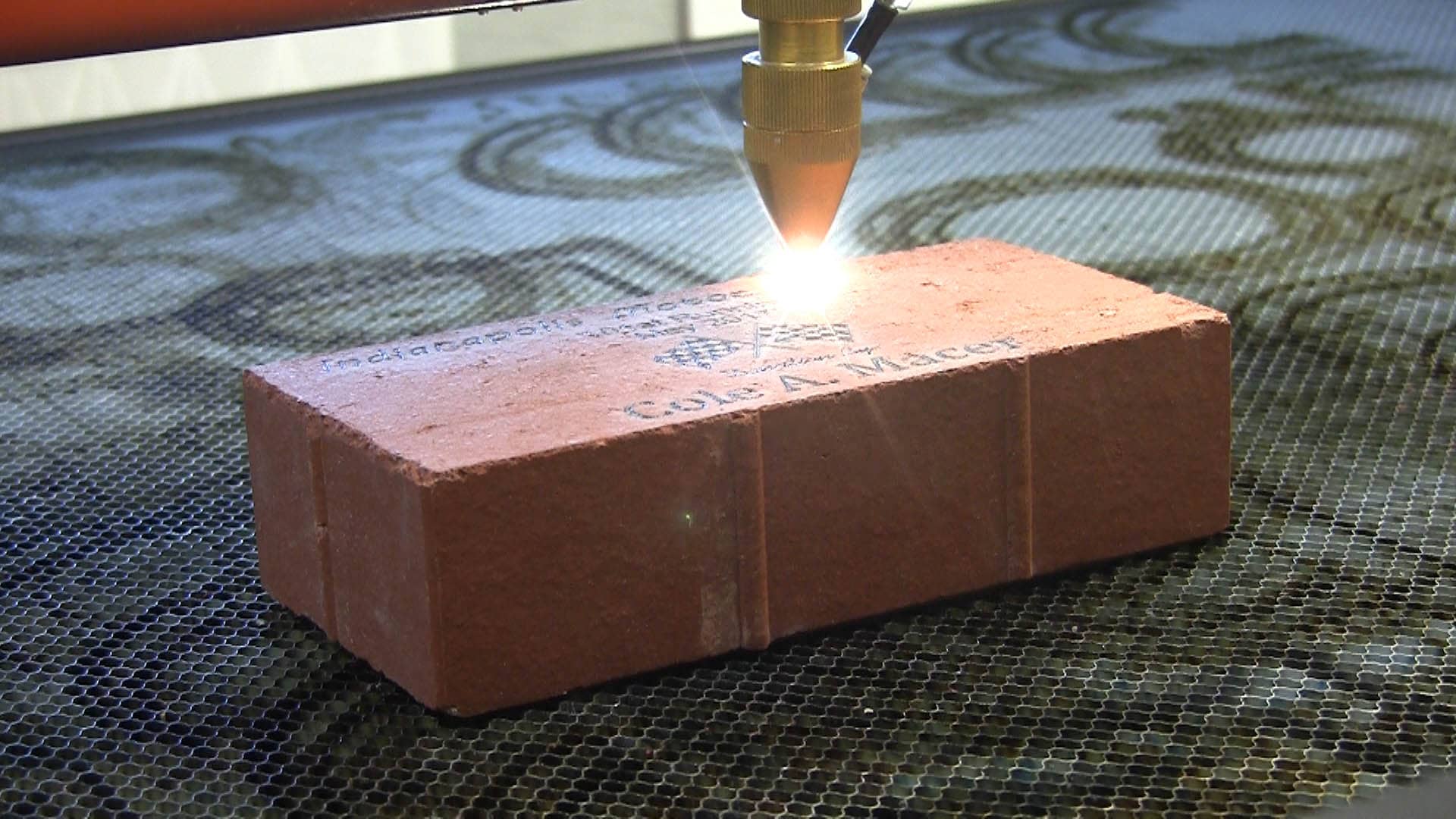

1. Laser Engraving Brick is a Simple Process. Laser engraving bricks is a much simpler process than sandblasting or photographing. Just create your design in the design software of your choice, send it to the laser, and push start. You can even engrave multiple bricks at once!

2. Produce High Detail Designs Without Worrying About Integrity. Because the beam of the laser is millimeters in width, achieving high detail designs with crisp edges is simple. Nearly any font can be used when engraving a brick. Logos, clip art, and even custom artwork can be engraved into brick, providing your customer’s many options. When using traditional methods of engraving bricks, you are limited by the size of the chisel.

3. Laser Engraving Brick Doesn’t Affect Integrity Speaking of integrity, when laser engraving brick, the structural integrity of the brick itself is not altered. Through the brick engraving process, the engraving on the brick becomes a stronger more durable material when finished.

When sandblasting or pantographing, actual pieces of the brick are chipped away, making the brick less durable than it was, to begin with.

No Fillers or Epoxies are Needed WhenLaser Engraving Bricks. Laser engraving bricks is essentially a green process. No other chemicals, fillers or epoxies are needed to complete the job.

When sandblasting brick, a filler is typicaly used to fill the chipped away areas. Elements like sunlight, acid rain, and other harsh weather conditions will cause deterioration over time. When a filler is not used, moisture will get into the letters. If it freezes, or mildew/algae grow in the text, the brick will break down over time.!

4. Laser engraving bricks are low maintenance. A laser engraved brick produces a smooth, hard, and permanent mark. Dirt and debris can easily be washed away. The mark will remain beautiful and clear for generations to come.

5. The Money Making Doesn’t Stop with Brick Engraving When you have a laser engraver for brick, you also have a machine that can alter the surface and look of dozens of other materials. This makes the diversification opportunities endless

Your AP Lazer can transform dozens of materials from ordinary to priceless! Laser engrave wood, acrylic, granite, marble, and many other common materials. The sky is the limit when it comes to generating revenue with this versatile tool.

If you’d like to speak to a representative or learn more about our

versatile brick engraving machines, call us at 1-800-585-8617